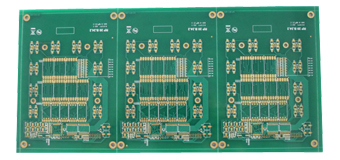

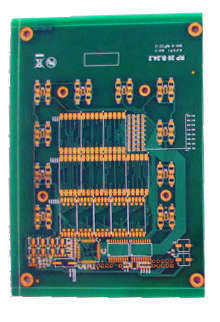

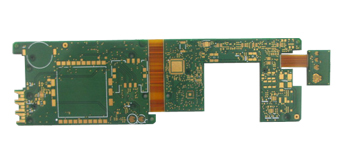

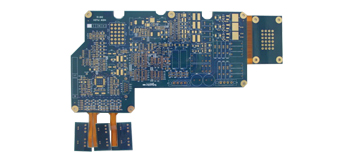

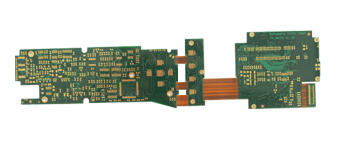

Desky plošných spojů/flexibilní plošné spoje

Počet vrstev |

1 ~ 64 vrstev |

|

|

Typy laminátu |

FR-4(High Tg, Halogen Free, High Frequency) FR-5, CEM-3, PTFE, BT, Getek, Aluminium base,Copper base,KB, Nanya, Shengyi, ITEQ, ILM, Isola, Nelco, Rogers, Arlon |

||

Tlouštka |

6-240mil |

||

Max tloušťka Cu |

210um (6oz) pro vnitřní vrstvy 210um (6oz) pro vnější vrstvy |

||

Min průměr děr (mechanicky) |

0.2mm (0.008") |

||

Aspect ratio |

12 : 1 |

||

Max rozměr panelu |

Jednostranné, oboustranné: 500mm*1200mm, Vícevrstvé: 508mm X 610mm (20" X 24") |

||

Min šířka cesty |

0.076mm / 0.0.076mm (0.003" / 0.003") |

||

Via hole type |

Blind / Burried / Plugged(VOP,VIP…) |

||

HDI / Microvia |

ANO |

||

Povrchová úprava |

HASL Lead Free HASL Immersion Gold (ENIG), Immersion Tin, Immersion Silver Organic Solderability Preservative (OSP) / ENTEK Flash Gold(Hard Gold plating) ENEPIG Selective Gold Plating, Gold thickness up to 3um(120u") Gold Finger, Carbon Print, Peelable S/M |

||

Pájecí maska |

Zelená, Modrá, Bílá, Černá, Transparent, atd. |

||

Impedance |

Single trace,differential , coplanar impedance controlled ±10% |

||

Obrys DPS |

CNC Routing; V-Scoring / Cut; Punch |

||

Tolerances |

Min Hole tolerance (NPTH) Min Hole tolerance (PTH) Min Pattern tolerance |

±0.05mm ±0.075mm ±0.05mm |

|

- LAMINATE SHEAR

- INNERLAYER IMAGE

- I/L ETCHING

- AOI INSPECTION

- LAMINATION

- DRILLING

- P.T.H.

- PANEL PLATING

- OUTERLAYER IMAGE

- PATTERN PLATING

- O/L ETCHING

- INSPECTION

- LIQUID S/M

- SCREEN LEGEND

- Immersion gold

- FINAL SHAPING

- ELECTRICAL TEST

- VISUAL INSPECTION

- O.Q.C

- PACKING&SHIPPING

-

Auto material cutting machine, cut sheet size 37*49inch, 41*49inch, 43*49inch to working PNL size.

Check point:

1.Base Material Type

2.Dimension

3.No Dent、No Scratch

4.Quantity -

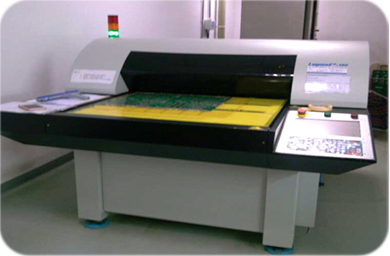

laser direct imaging

Check point:

1.Correct CAM data

Auto exposure machine

Check point:

1.Energy

2.Vacuity

3.Environment

Develop check point:

1.Temperature

2.Pressure

3.Concentration -

After development, the non-product copper is etched away.

Check point:

1.Temperature

2.Speed、Pressure

3.Concentration

4.Line width/space -

AOI(Automatic Optic Inspection)

Check point:

1.Open/short

2.Copper Residue -

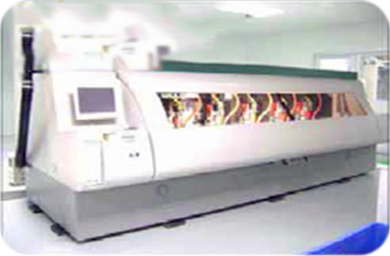

Horizontal black oxidation

Check point: 1.Concentration 2.Temperature 3.Coating ThinknessVertical black oxidation

Check point: 1.Concentration 2.Etching Rate 3.TemperatureVacuum high-presure laminated machine

Check point: 1.Temperature 2.Temp. increase Rate 3. Pressure

Quality check point: 1.Board Thinkness 2.Delamination 3.Appearance -

Mechanical drilling

Check point:

1.Hole Size

2.Hole Wall Roughness

3.Registration

4.The amount of holes

5.Appearance

Laser drilling, drill micro via holes

Check point:

1.Laser drill completely

2.Hole diameter寸

3.Hole shape -

Plasma desmer

Check point:

1.Plasma parameters

2.Mixed gas species

3.Power energy

4.Working pressure, processing time and gas flow rate

Plate through holes

Check point:

1.Temperature

2.Concentration

3.Plating Rate

4.Back Light Test -

Horizontal plating

Check point:

1.Temperature

2.Concentration

3.Current Density

Vertical plating

Check point:

1.Temperature

2.Concentration

3.Current Density -

laser direct imaging

Check point:

1.Correct CAM data

Auto exposure machine

Check point:

1.Energy

2.Vacuity

3.Environment -

Pattern plating

Check point:

1.Temperature

2.Concentration

3.Current Density

4.Check scratching the tin on the lines

Quality check point:

1.Hole Wall Thk.

2.Surface Copper Thk.

3.Apperance -

The non-product copper is etched away.

Check point:

1.Temperature

2.Speed

3.Pressure

3.Concentration

4.Line width/space -

AOI(Automatic Optic Inspection)

Check point:

1.Open/short

2.Copper Residue -

Spry coating line

Check point:

1.No Exposure copper

2.No Mask on Pad

3.No Scratch, Scum -

Auto-printing

Check point:

1.correct CAM data

2.Registration

3.Definition

4.No scratching -

Immersion Gold

Check point:

1.Temperature

2.Concentration

Quality check point:

1.Au / Ni thickness

2.Phosphorus percent

3.Apperance

Hot air leveling

Check point:

1.Angle of Air Knives

2.Solder Bath Temp.

3.Air Knives Temp.

Quality check point:

1.Sn/Pb Thinkness

2.Apperance -

CNC routing for finish board size

Check point:

1.Dimension

2.No Powder Residue

3.No Scratch -

Flying probe tester

Check point:

1.Open

2.Short

3.Circumferential Separation -

Fanal quality control, visual inspection

Check point:

1.Scratching

2.Crease 3.Oxidation

4.Solder deviation

5.Drill deviation

6.Conductor nick

7.Copper residue and so on -

SIR Oven

Surface insulation resistance testingThermal cycling chamber

Thermal cycling testing3D Dimension

X-ray measuring instrument Measuing gold thickness, nickel thickenss, solder thickness and so on

- Cutting

- D/F Lamination & Exposure

- D.E.S.

- AOI

- CVL Lamination

- Black / brown oxygen

- Lay up

- Laminating

- NC Drilling

- Plasma

- P.T.H

- D/F Lamination & Exposure

- D.E.S.

- LPI

- Surface finish

- Silksreen

- E.T

- Assembling

- Punching/Routing

- FQC

- Packing

-

Cutting:

Coil material cutting piece material

Check Ponit:

Dimension/Thickness -

D/F Lamination & Exposure:

Graphic transfer

Check Ponit:

Film transmittance/expansion/contraction/appearance and revision -

D.E.S:

Graphic transfer

Check Ponit:

Trace width/Trace space/open/short -

AOI:

Automated Optical Inspection

Check Ponit:

Open/Short -

Coverlay:

Paste insulation protective film

Check Ponit:

Missing opening/Offset/Excessive glue/CL On pad/Dust/Copper Exposed -

Black/brown oxygen:

To increases the joint force between each layer for mulitlayer -

Lay up:

Stack up each layer for multilayer

Check Ponit:

Offset/Foreign matter -

Lamination:

By high temperature and high pressure makes each layer get together

Check Ponit:

Thickness/Delamination/Layers of board -

NC Drilling:

Drill hole for basefilm/stiffener/coverlay

Check Ponit:

Hole diameter/degree of deviation/quanity of holes -

Plasma:

Desmear process -

PTH:

Ensure the conduction of each layer

Check Ponit:

Copper thickness and back light -

D/F Lamination & Exposure

:Graphic transfer

Check Ponit:

Film transmittance/expansion/contraction/appearance and revision -

D.E.S:

Graphic transfer

Check Ponit:

Trace width/Trace space/open/short -

LPI:

Print solder resist ink

Check Ponit:

SM on pad/Missing SM/SM off normal/Dust/No developing cleanness -

Surface finish:

Plating metal protective film on pads,it's protect pads,and convenient in SMT

Check Ponit:

Exposured copper/Gold thickness -

Silksreen:

Print Comp Symbols and logos on board

Check Ponit:

Legend on pad/Legend obscure -

ET:

Ensure electrical function, avoid open/short circuit

Check Ponit:

Open/Short -

Assembing:

Paste Stiffener(PI/FR4/AL/SUS) and tape

Check Ponit:

Offset/Excessive glue/Dust -

Punching/Routing:

Cutting the profile of board

Check Ponit:

Dimension -

FQC:

Final Quality Control For Product

Check Ponit:

Appearance inspection -

Packing:

Protection products, to avoid damage in transit