Assembly

Technologie | Hersteller | Model | Menge | Technische Kompetenz | |

SMT Linien |

4 |

|

|||

DIP Linien | 7 | ||||

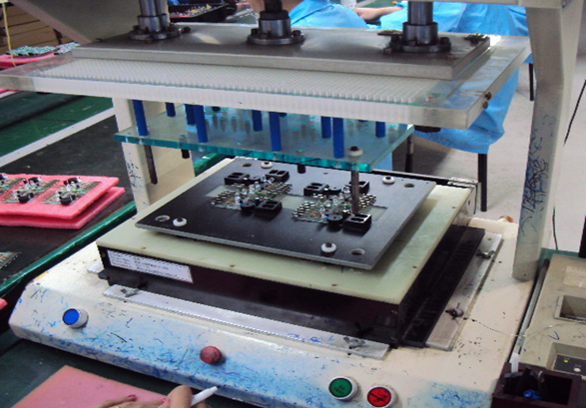

Siebdruck | BESTIME | T1010A | 4 | Max. Ausmaß der Platte: 410*360*4mm | |

Glue dispenser | JUKI | Kd2077 | 4 | ||

Chip SMT |

JUKI |

FX-3 |

4 |

1) Chip Komponente – Widerstände, Kondensatoren, usw. Geschwindigkeit: 36,000CPH

2) |

|

IC SMT |

JUKI |

2080 |

4 |

1) Für IC, BGA, usw. Geschwindigkeit: 11,000CPH |

|

Reflow Löten | JT | NS1000 | 4 | ||

AOI Kontrolle | Omron | VT-RNS2 | 4 | Desktop High Speed Version | |

Axial Einfassung | Panasonic | AV131 | 2 | ||

Radial Einfassung | Panasonic | RL132 | 1 | ||

Wellenlöten | JT | JT350 | 7 | ||

ICT Test | JET | JET300 | 7 | ||

Internes Labor |

3D Test |

||||

Quality Standard | IPC-610D |

-

Sampling Inspection:

PCB & Mechanical Parts AQL

PCB...0.25 MA, 0.65 MI

MECH...0.65 MA, 2.50 MI

-

Condition:125℃ 2H After remove moisture, ensure product quality, easy to operation

-

Automated Under Screen Cleaner 2D Optical Screening

-

Attaching chip components to the surface of the board. Board pads are soldered. No holes used in process.

-

Make the boards and components fully combined

-

Desktop High speed Automated Optical Inspection machine. Inspection items: missing, shift, miss alignment, reverse, polarity, other component, bridge, dirt, dust, no solder, short solder, cold solder, lifted chip, lifted lead, un-insertion. OCR: optical character recognition/verification. After Printing Process: No solder paste, excess, blur, scratch, short, shift, bridge.

-

Process of inserting axial & radial components on Printed Circuit Board

-

Lead of inserted components in manual insert are cut

-

Make the boards and components fully combined

-

Retouch of components soldering

-

100% Test Inspection